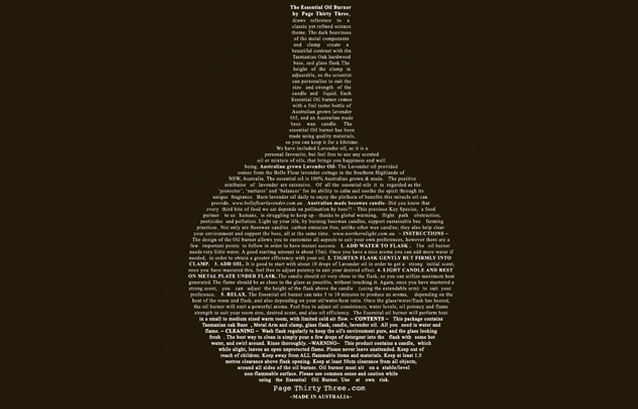

Like any good design, the Page Thirty Three Oil Burner is born of the passion of the designers themselves. “Bianca has always been really interested in the healing potential of essential oils”, they explain, and the couple had researched and experimented with the various combinations over the years. Not having found oil burners of satisfactory stylistic and functional quality, the logical next step was to create one themselves.

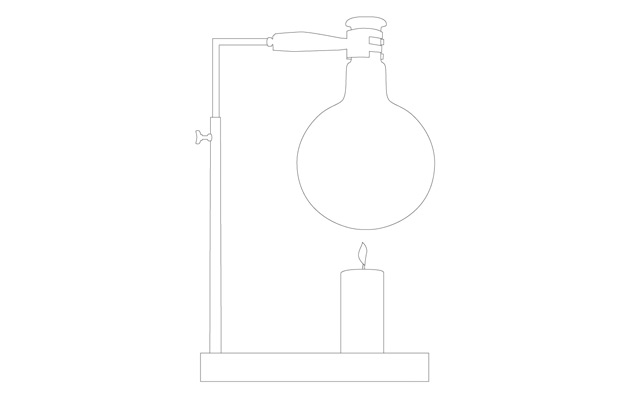

Aesthetically, the attraction to the look and feel of old alchemical and chemistry equipment reflects their belief that “nostalgia plays a large role in the emotive aspects of design”. However with vintage and retro so in vogue, the pair were conscious of wanting to avoid any transitory fashions, and as such felt it was important to ground the design with genuine function.

“The first draft of the design was awesome”, they enthuse, “it was made from vintage components, and was very crude”. However its ‘retroness’ and estimated retail price of over $1000 forced the designers to a meticulous and intelligent re-evaluation of parts, materials and sourcing. A first round of research took them to a science supplies store, where they bought all the components to set up a flask and retort stand. “We lit a candle, added some oil and water, and within 5 minutes, the room was filled with a wonderful lavender scent… that was a great moment”.

Throughout the process the main recurring obstacle was that no matter how resourceful and efficient the choice of materials and reduction in number of parts, having a manufacturer create the product added a percentage of cost that pushed the final retail price above their desired point. The solution was to bring the manufacturing in-house: “[we] set up a basic workshop, source components locally and globally, then consolidate, package and finish at the workshop ourselves”. Nonetheless they faced a crucial dilemma; to stick to their desired price they could either produce the whole product in Australia but downgrade quality of wood and not include a candle or oil, or they could import some components, complete production in-house and include all the extra elements necessary to use the burner straight out of the box.

They chose the latter option, and are grateful for the “joy associated with hand finishing every Oil Burner.” And, judging buy the overwhelming positive reaction (“We have been making Oil Burners non stop for about a year now”), they chose correctly.